We support our Customer Network ranging from local to global with our high quality products

Having a dream is not enough to secure a sustainable world. We take action for making our dreams come true. We produce secondary aluminium from recyclable scrap and other similar materials and lead the way for other manufacturers in the same field in Turkey. We expand our production volume through our experience and innovative efforts and meet the expectations of our global customers. We celebrate our justified pride of being ranked among the largest 500 manufacturers of the country.

We manufacture homogeneous and high performance liquid metal on our production lines by taking materials of different alloys and forms, pass them through our sorting lines with the expertise of our teams and make them available for our re-melting process.

Our raw material resources are re-melted in our reverberatory, induction and rotary furnaces with the highest efficiency rates.

Using our high capacity furnaces, we undertake aluminium semi-product casting in accordance with the international alloy standards.

We subject cast products to tests at our laboratories equipped with the state of the art quality control systems. We ship to our customers only our latest technology engineered products that fully conform to the international quality norms and standards.

We pay attention to the shipment of our products as we do during the production phase. We bring together our product groups with our customers as and where it is needed.

We create values for the global metal sector with our wide-ranging product portfolio and our years long experience in metal processing with a capacity of higher than 190 thousand tons annually.

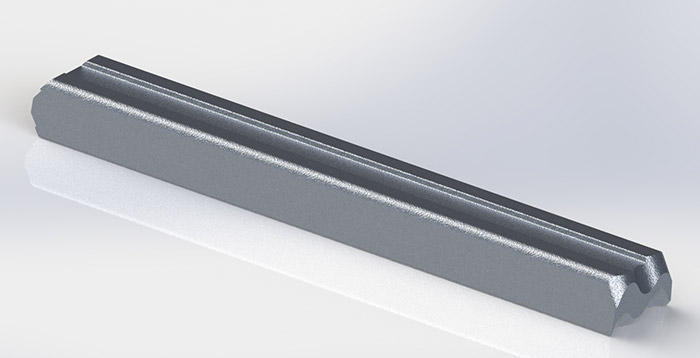

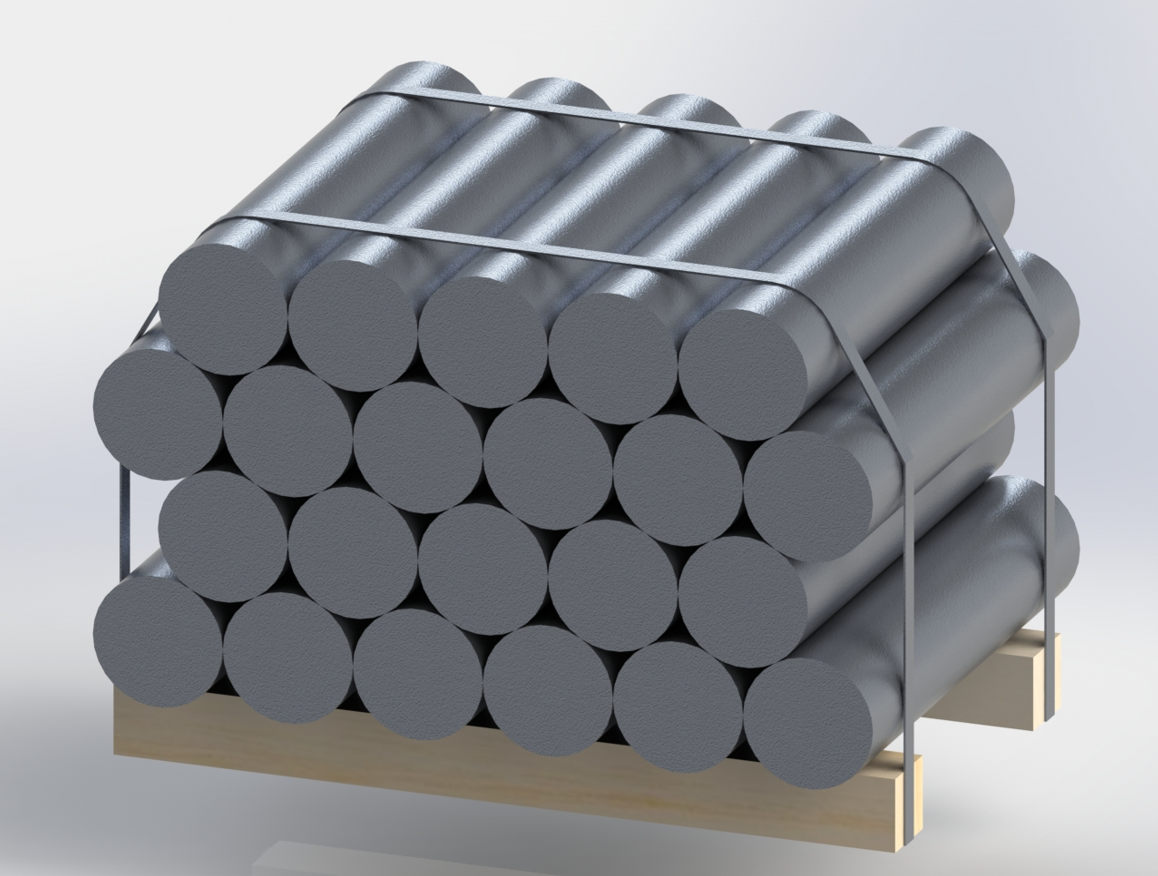

Alloyed Log

Technical Characteristics:

* Unit Weight: 6-8.5 kg

* Pallet Weight: 500-1.000 kg

* Length: 50 – 80 cm

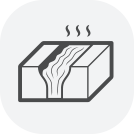

Alloyed Ingot

Technical Characteristics:

* Unit Weight: 6-8.5 kg

* Pallet Weight: 500-1.000 kg

* Length: 50 – 60 cm

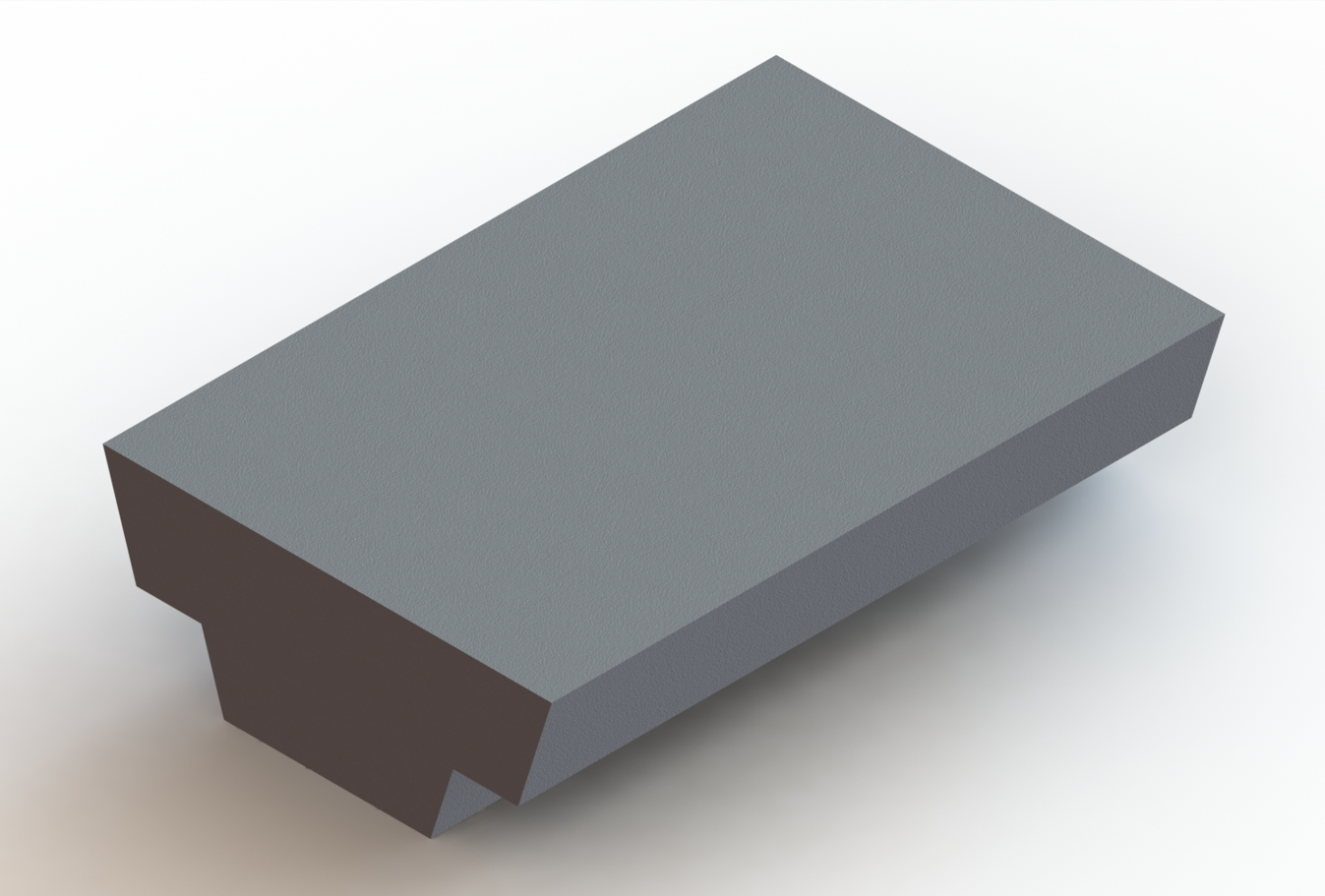

T-Bar

Technical Characteristics:

* Unit Weight: 450-650 kg

* Dimensions: ~ 1100 x 970 x 320 mm

Şahinler Metal Billet Casting line uses a fully automated computer-aided, hot top casting system to control the casting process and produce exceptionally superior quality aluminium billets that adhere to the highest European EN AW quality standards. The raw material in the form of ingots are transformed into billets with the diameters of 5”, 5.5”, 6”, 7” and 8” through EN AW 1xxx, 6xxx and 7xxx series of Al. alloys. In addition, the manufactured billets are subjected to a 100% ultrasonic testing. Following the homogenisation & quenching processes, micro structure checks and grain boundary analysis are also performed, respectively.

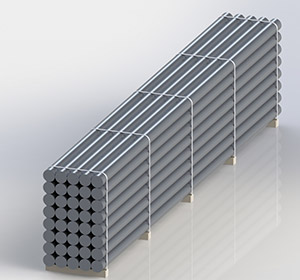

Billet

Technical Characteristics

* Diameter: 127 / 140 / 152 / 178 / 203 mm

* Length : Special Cut Length: From 30 cm – Any Custom Size

* Maximum : 6.3 m

* Alloys: EN AW 6063 a&b /6082 / 6005 / 6005a / 6060 / 6061 and EN AW 1xxx series

7.000 Series Special Alloy Defence Industry Billets

Technical Characteristics

* Diameter: 127 / 140 / 152 / 178 / 203 mm

* Length: Minimum : 50 cm

* Maximum : 6.3 m

* Alloys: enaw 7050 / 7075

Deoxidant Ingot

Technical Characteristics

* Unit Weight: 2-6 kg

* Pallet – BIG BAG Weight: 1.000-1.500 kg

* Aluminium Content: 95 – 99 %

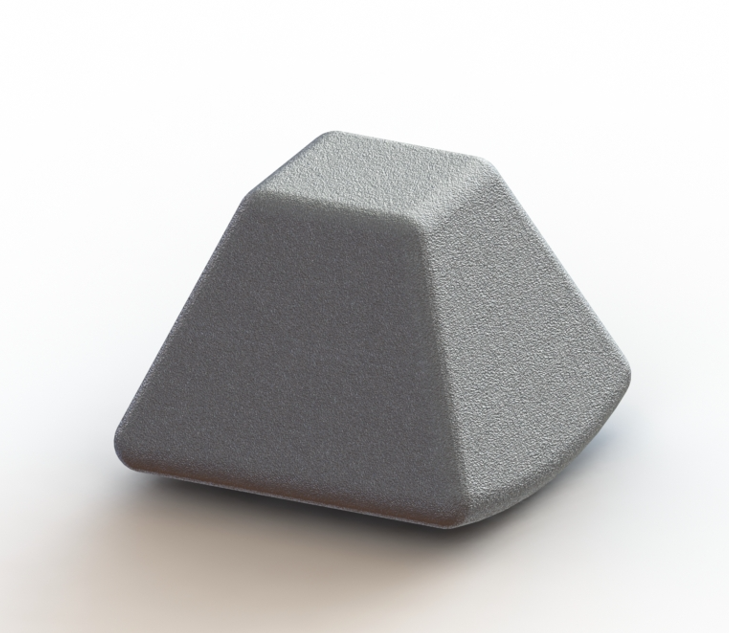

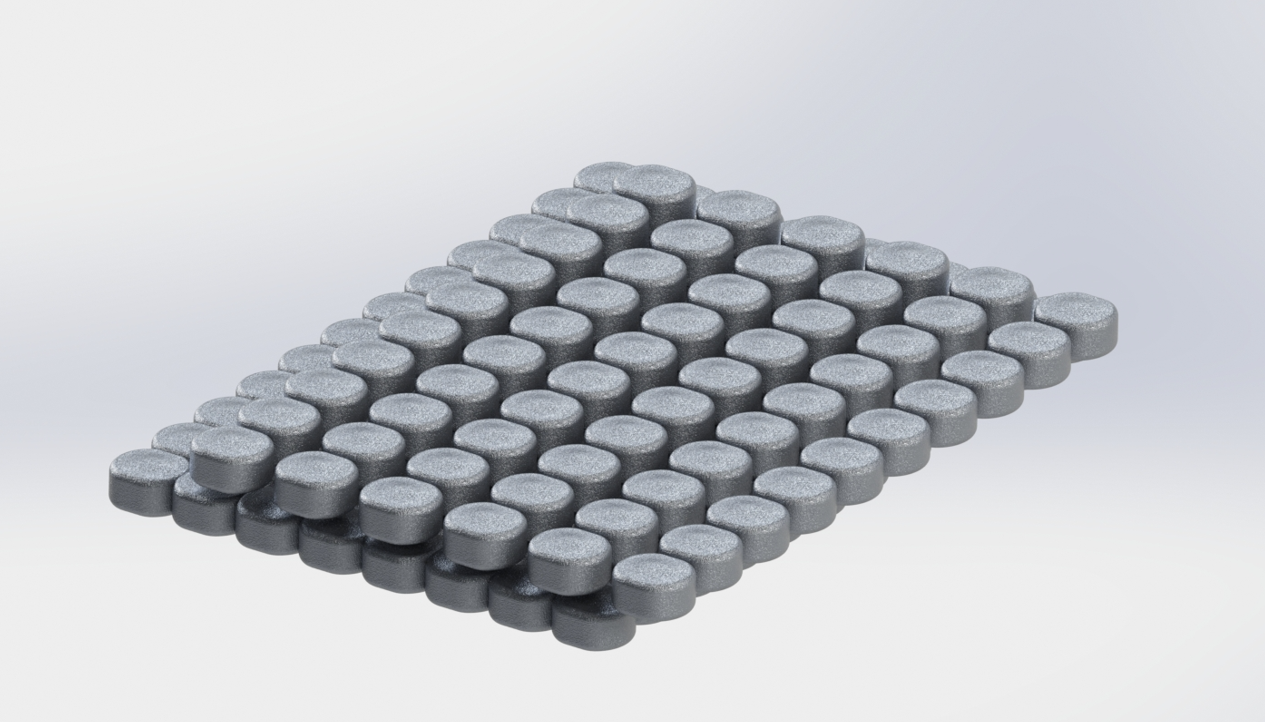

Deoxidant Pyramid / Semi-sphere

Technical Characteristics

* Unit Weight: 100-370 g

* Pallet Weight: 1.000-1.500 kg (in Big Bags) * Aluminium Content: 95 – 99 %

Deoxidant Teardrop Shaped (Granule)

Technical Characteristics

* Unit Weight: 1-2 g

* Pallet – BIG BAG Weight: 1.000-1.500 kg

* Aluminium Content: 95 – 99 %

![]() 0216 304 05 06

0216 304 05 06

![]() 0216 304 05 05

0216 304 05 05

![]() info@sahinler.com.tr

info@sahinler.com.tr

![]() 0312 267 00 50

0312 267 00 50

![]() 0312 267 00 54

0312 267 00 54

![]() info@sahinler.com.tr

info@sahinler.com.tr